FAQ: Brushy Creek Wastewater Treatment Facility

Jan. 13 public meeting presentation

On Thursday, Jan. 13, 2022 the City of Bryan held a public meeting hosted by the Texas Commission on Environmental Quality (TCEQ) regarding the future Brushy Creek wastewater facility. If you were unable to attend this meeting, you can view the slides from the presentation that was given.

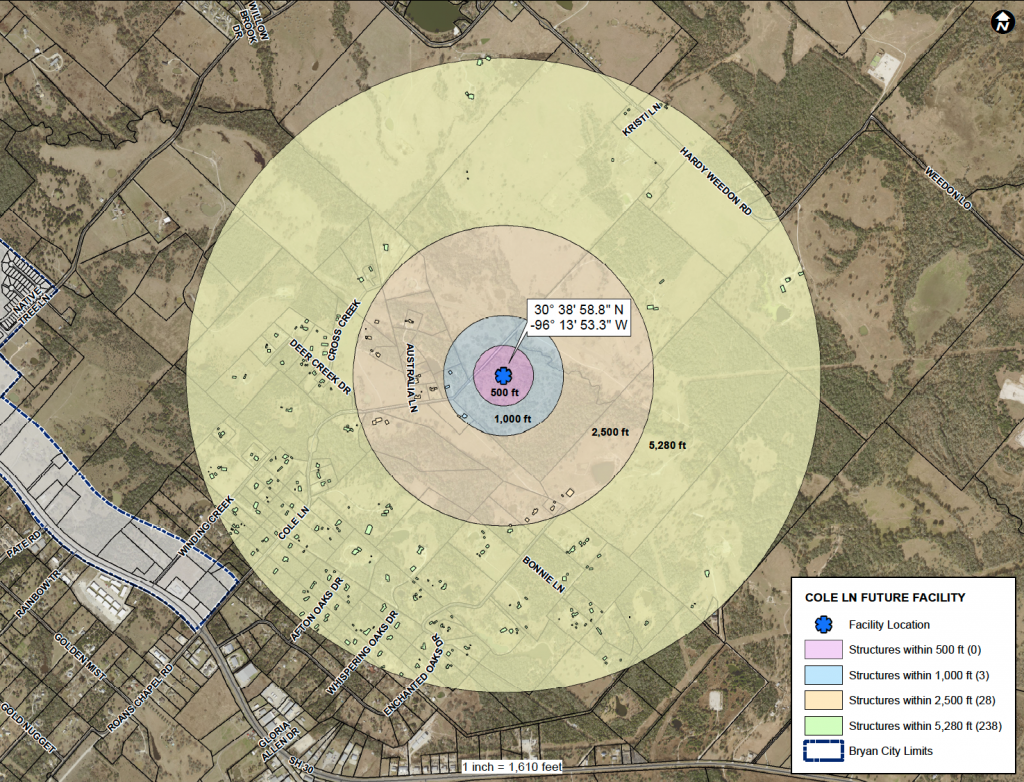

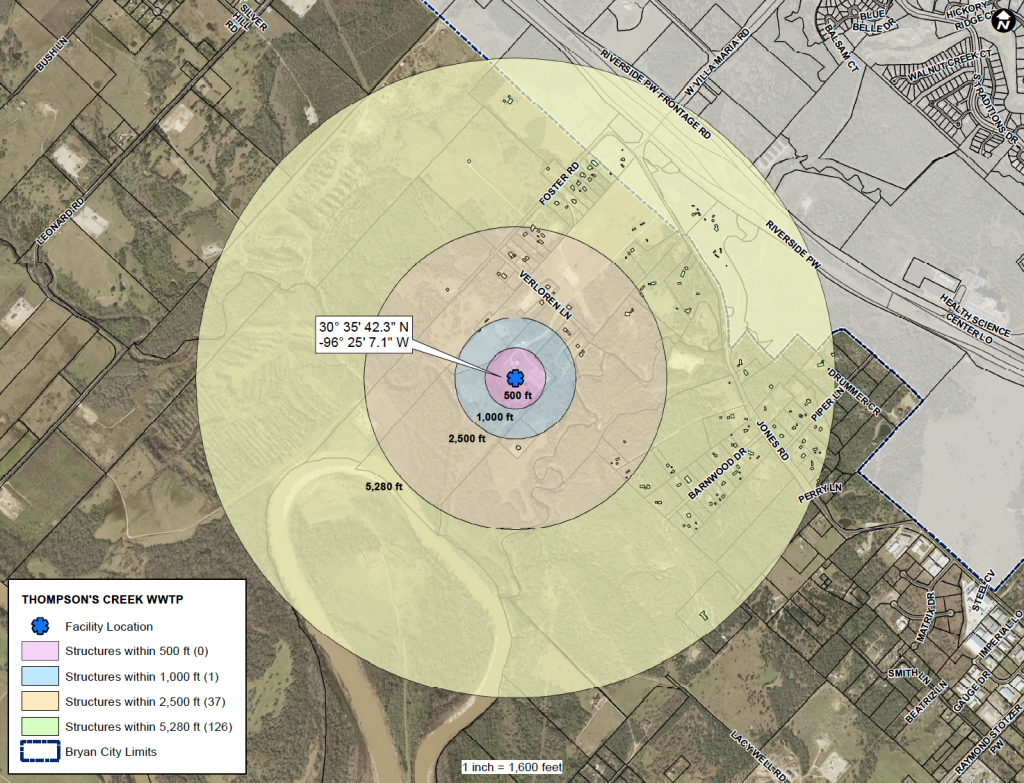

Comparing the future facility to an existing one

These two images compare the future Brushy Creek facility off of Cole Lane to the existing Thompson’s Creek facility. They show the number of existing structures located within one mile of each of the sites.

Frequently Asked Questions

When did the City purchase the land and how many acres did they buy?

The City Council approved the purchase on April 23, 2019. The City purchased the 75 acre property in Spring 2019.

Why did the City of Bryan select this tract of land?

The property was purchased after evaluating several sites on the east side of Bryan. The evaluation included roadway access, location within the watershed, and floodplain.

Why is the City building the treatment plant?

The purpose of the plant is to support growth on the east side of Bryan and eastern Brazos County as development from Bryan moves eastward.

Where does the effluent go when it leave the new plant?

The plant is in the Brushy Creek watershed that drains eastern Bryan and portions of east Brazos County. Discharge of the wastewater will travel from Brushy Creek to the Navasota River, then to the Brazos River.

How large is the plant, and how many acres will be used for the facility itself?

The permit application is for 12 MGD (million gallons per day). The first phase of plant construction will be 4 or 6 MGD. The plant will take up about 6 acres.

Will there be any buffer between adjacent property owners?

State requires a minimum buffer of 150-feet which the City intends to keep vegetated.

How much flow will the plant have when it is constructed?

Actual flow to the plant will initially be 50% of plant capacity, which is 2 to 3 MGD. Once 75% of the plant’s capacity is reached, planning has to be in progress for the next phase and has to be under construction by the time 90% of capacity is reached.

When do you plan to build the facility and how long will it take?

Design phase for the plant will take two years. The construction phase for the plant will take three years after design is complete.

How were the discharge limits determined?

Environmental analysis of the receiving stream has been performed by TCEQ to determine the discharge limits placed on the City’s effluent flows.

How do we know that the creeks and streams will not be harmed?

The discharge limits along with other state and federal rules will protect the water quality in Brushy Creek and potential uses of the stream.

How much traffic will the plant generate?

Once the plant is operational, vehicular traffic will include a plant operator going to the site, a truck hauling solids away from the plant to the landfill, and an occasional maintenance truck or lab vehicle. Solids disposal will probably occur two times a day.

Don’t sewer treatment plants smell?

Newer technology in plant design results in much less odor than from older plants such as the Burton Creek Plant off of Park Lane.

Will the treatment plant cause issues with wildlife?

The site has been determined to not have threatened and endangered species, and does not have cultural or historical features.

Are there any other issues on the site that may have an environmental impact?

A potential wetland on the site will remain undisturbed during construction of the plant.

What new technology is used to make this plant different from older plants still in use today?

Treatment processes that have the potential to emit odors will be covered and the odorous air in these treatment processes will be collected and treated. UV light disinfection of the effluent will be utilized to limit the amount of chemicals on the site. High efficiency equipment with sound enclosures will be used to limit the amount of equipment noise. Computer monitoring of the process and equipment eliminates disruptions in treatment due to equipment malfunction.